Pallets 101

Examining today’s options for this building block in the supply chain

The pallet is the staple of today’s supply chain. Ever since its invention in the early 1900s, the pallet has transformed the way we store and move products.

Prior to the introduction of pallets, the merchandise was transported in a variety of ways: everything from wooden crates to barrels, kegs, and boxes. One other popular pre-pallet mode was the “skid,” which is actually believed to date back as far as ancient Egyptian times.

The pallet, some say, is an improved version of the skid. The invention of the forklift truck in 1915 led to greater use of pallets. History tells us that pallets were used in rail shipping during the 1920s, and according to Reusable Packaging News the use of the pallet and forklift was a key component of the U.S. Military logistics strategy during World War II.

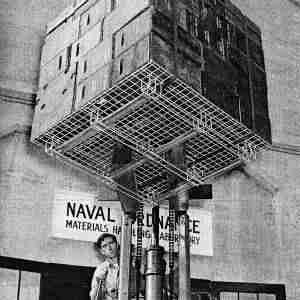

A steel pallet being used in WW2.

A significant improvement came in 1945 with the emergence of the first four-way pallet. This new version could easily be picked up from any side with motorized equipment such as a forklift or pallet truck.

Pallets, which the magazine Inbound Logistics characterizes as “where the rubber meets the road…in the global supply chain,” are seemingly everywhere today. They are widely used in warehouses for shipping and receiving functions, are integral in the transportation component of the supply chain, and can be seen in retail displays at big box stores such as Walmart, Costco, Home Depot, and others.

While today’s pallet may bear resemblance to its 1900s counterpart, today’s warehouse/logistics managers and manufacturers have more choices than what was available a century ago. For today’s supply chain needs, you can choose between wooden, plastic, aluminum, and steel pallets.

What’s the best choice? Really, the question is, “What type of pallet is best for your needs?”

There are severe limitations with wood pallets, particularly in industries such as pharmaceutical and baked goods (but not limited to them). Plastic and aluminum often lend themselves more favorably to today’s warehouse and supply chain needs.

We’ll examine the pros and cons of the different types of pallets available. But first, let us share a few initial observations.

- It’s critical that the pallets you purchase work with your existing equipment and environment. The pallets should be uniform and consistent in size to conform to any supply chain, conveyor, or automation requirements that you have.

- How important is the anticipated life cycle of the pallet in your consideration?

- Due diligence is key! Don’t rely on a web page picture or a catalog description for this important purchase. If you are involved in the storing, shipping, or receiving of valued cargo, you’ll want to do the appropriate research and testing.

- Try before you buy! Ask the distributor for a sample pallet or two and really put them to the test. How do they perform in your environment?

- On the practical side, evaluate how they will stack up and rack in your warehouse. Are they difficult to move around and transport items and how easily can you clean, sanitize and dry them?

- Remember that the pallet is an intricate part of your quality control. We’ve seen customers who ship their plastic pallets to suppliers because they know that these pallets work in their environment. Find out what works for your customers and suppliers’ needs.

To summarize, be very strategic in selecting the pallets you will use. Do your research. And if you have questions, contact an industry expert.

Look out for part 2 of Pallets 101 coming soon.